Premium Construction Solutions

At AMA International USA, we take pride in offering a comprehensive range of services to meet all your building construction needs. With a focus on quality, reliability, and customer satisfaction, we are your one-stop solution for top-quality construction materials and services.

Cement Mixers

Our state-of-the-art cement mixers are engineered for efficiency and precision. Whether you're working on a small-scale project or a large construction site, our mixers deliver consistent results, ensuring smooth and uniform blending of cement for every pour.

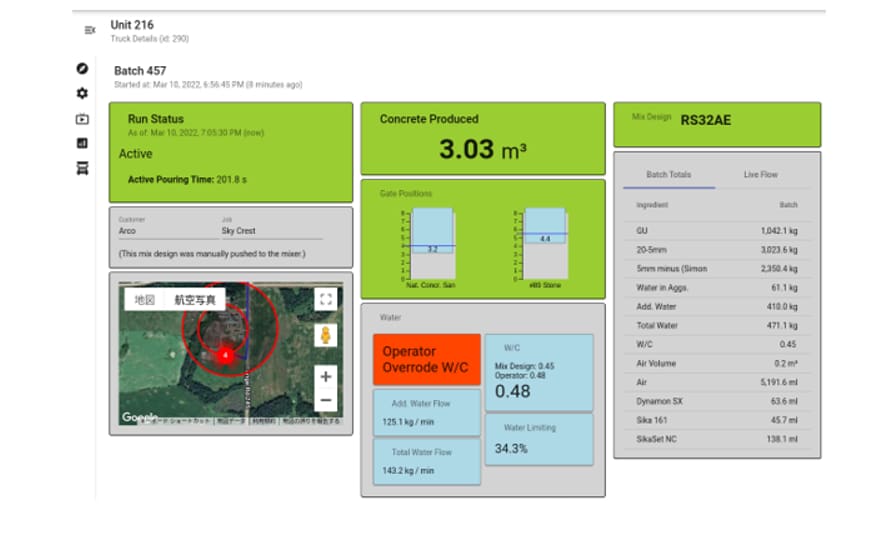

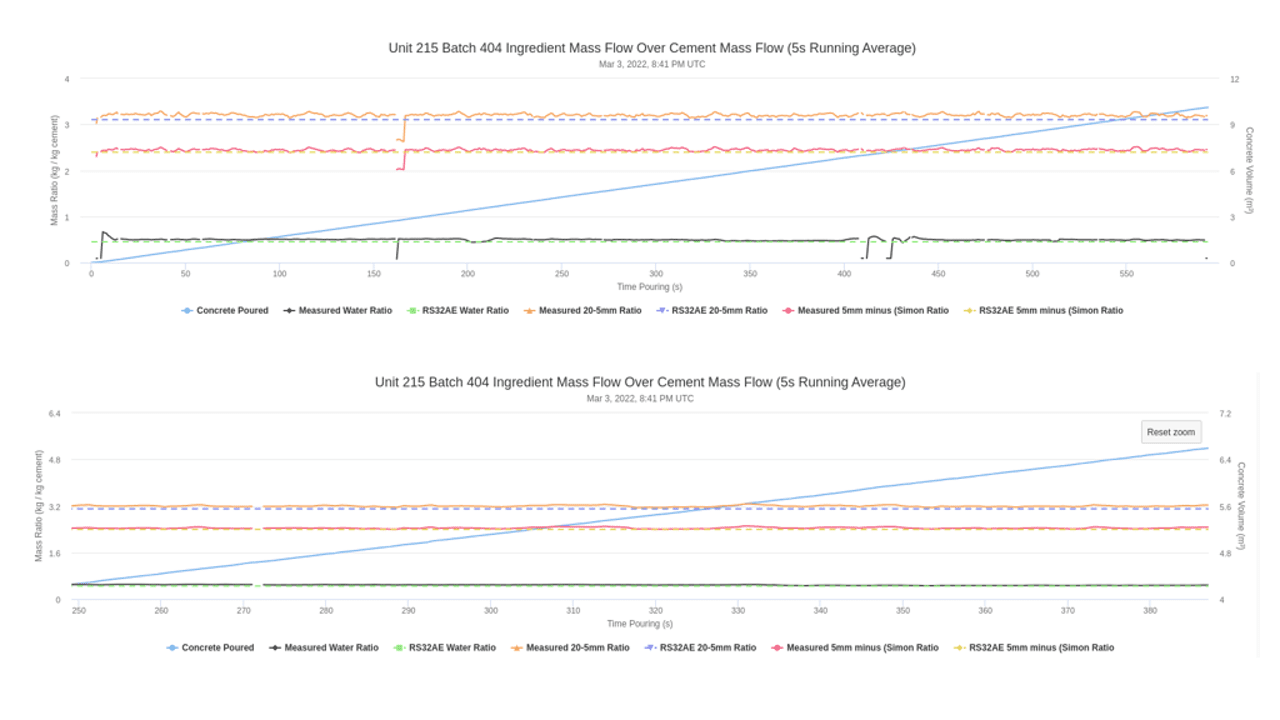

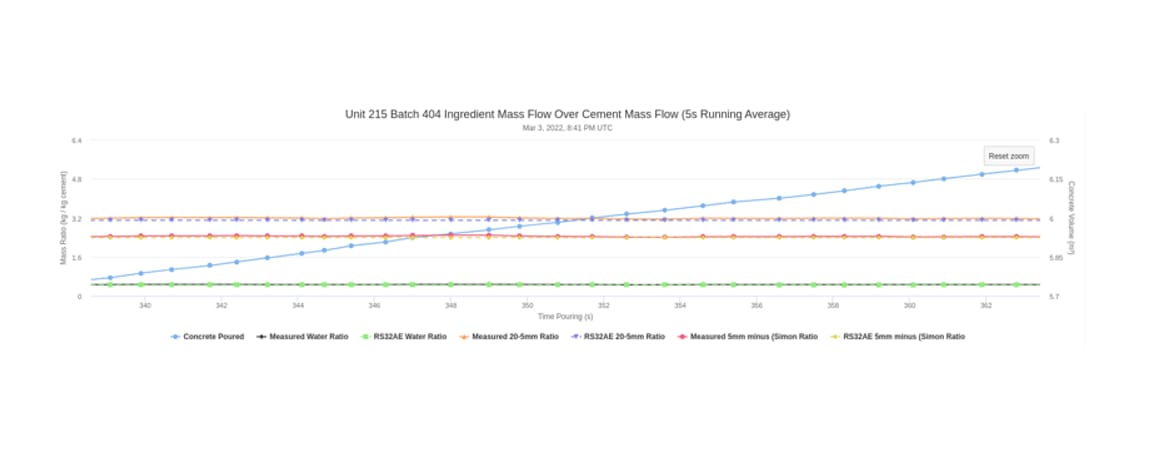

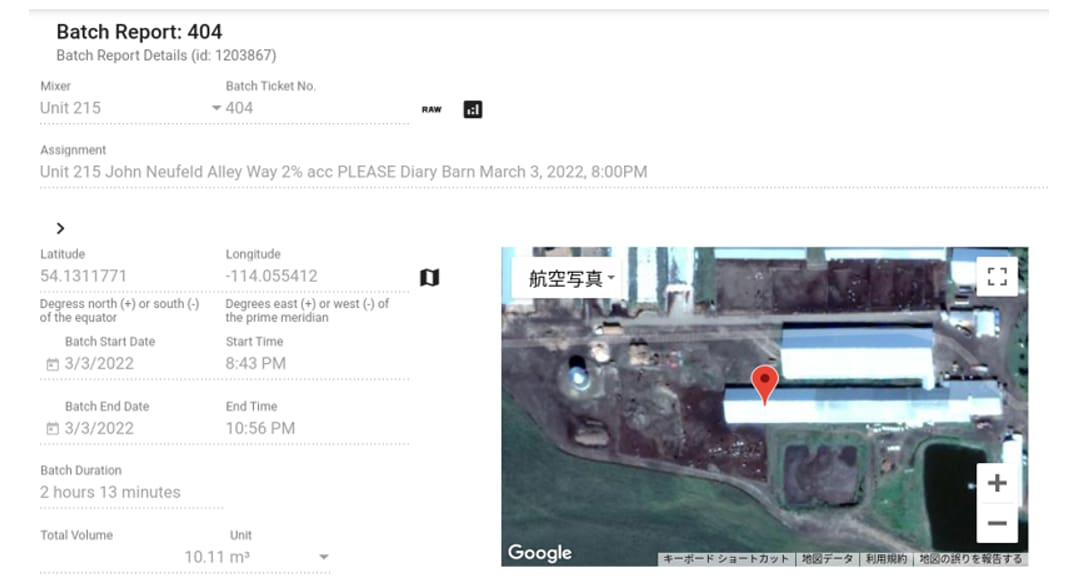

Our mixers are continuous-pour mixes and with every yard of concrete poured, we collect 7,000 data points to the cloud. No other concrete mixers can do this. We are at the forefront of this technology.

Our clients can see within a moment, the actual cement spc mix for there design.

Aggregate (Stone and Rock)

We specialize in providing high-quality aggregate sourced from trusted suppliers around the world. Our extensive selection of stone and rock ensures that you have access to the perfect materials for your construction projects. From gravel to crushed stone, we have it all to meet your specific requirements.

Contact Us Today

Ready to get started on your next construction project? Contact AMA International USA today to learn more about our services and how we can help you achieve your goals. Let us be your partner in building a better future.

QUALITY REPUTATION

Zero loads of concrete rejected

- Including for air, slump, consistency, temperature, time expired, and have over-achieved on every compression strength for every cylinder for every project it has supplied

100% for 13 consecutive years

- Success is related to attention to detail, Omni mixing manages most of the details enabling success for 1000’s of tests.

- Historical Performance is the strongest indicator of future performance

OMNI-MIXING TECHNOLOGY™

Accurate measurement

- More than 70,000 data points for each load of concrete

High Production rate

- Scalable from 10 to 65m3 per hour per unit

- Parallel production that doubles and triples

Full Transparency

- See what is produced real time

- No Surprises

- Centralized monitoring, decentralized production

Technical Leadership

- IOS iPad Control

- Concrete Cloud Ops™

Real-time Telemetry

Per-second Data

Automated Batch Records

The advantages of continuous concrete production:

the ability to produce concrete on-site

The ability to adapt the concrete produced to onsite conditions

Placer has 'DIRECT communication with Producer

Complete Transparen cy Production issues are visible

Logistics Peaks eliminated and are averaged over longer timeframe

No transport Heat Gain/Slump loss

The ability to repeatably duplicate the produced concrete/Visible Repe atability of mixing

Homogenous MixingStart/stop production in a moment

Increase Data Availability with 1000's of data points

Remote Monitoring and Inspection of Data

Fast Visual Data Interpretation

Increased / Scalable Production Rates

Industry’s Most Accurate Control System

Concrete Genius® Control System:

- Concrete Genius´ Base System (Functions)

- Using the system Calibrate the mixer based on weight, this happens by pressing calibrate and entering the weight into the system.

- When calibration is completed, the dispatcher sends the mix design to the truck from anywhere in the world.

- What happens next - the system calculates the required aggregate flow, it then determines and sets the gates, it calculates the maximum water flow rate, it measures the water flow and controls the water flow rate, it calculates the required admix per hundred weight, it measures, and controls admix. At the same time, it is measuring and recording the cement flow rate.

- All the above is happening in milliseconds. As it is measuring aggregate, cement, water, and admixtures it is controlling and recording constantly.

- Secure measurement ensures all concrete is recorded eliminating operators doing on the side cash jobs

An Operator Designed Mixer

Industry leading Innovations (Standard on all Mixers):

- All Modular Components With Heavy Duty Construction.

- Modular Ag Bin – 5 Panels, All Individually removable.

- 6020 aluminum aggregate panels in modular sections.

- Fully bolt together design to prevent work hardening, eliminating cracking.

- Molded cement bin to minimize air resistance and increase ultimate design strength for longer lasting life.

- Hydraulic tank that is cradle supported for convenience & longevity while increasing heat transfer for longer life.

- 70 year corrosion resistant high carbon frame.

The last mixer you will buy!

An Operator Designed Mixer

Innovations (Standard on all Mixers):

- Total weight of the mixer is 21% lighter, increases capacity by nearly 9%.

- Reduced Operating costs offering up to $15,000* savings per year over entire life. That is $1200/month* savings

- Fast change auger mounting system to facilitate the change of mixing augers.

- Removable top cover on auger for easier wash-out and maintenance.

- Open frame design to create easier access for cleaning, maintenance, and repairs. Change the belt in under 3 hours!

*based on decreasing transportation costs by 8%, your results may be higher

The last mixer you will buy!

An Operator Designed Mixer

Innovations (Standard on all Mixers):

- The highest production rate in the Industry.

- Non-Proprietary Parts! No down time, cost savings for you the customer.

- Admixture “Perfect Dosage” system mix or match up to 6 separate admixtures with up to 6 precision pumps for liquids and/or 4 finite powder dispensers for technical concrete with improved consistency and quality.

- Ability to perform a greater range of mix designs.

- Over designed High Torque hydraulic motors in every location, designed for 100% operational duty cycles even in the harshest environments.

The last mixer you will buy!

Industry’s Most Accurate Control System

Concrete Genius® Control System:

- Concrete Genius® Base System

- High precision cement based (per hundred weight) admix system.

- Low maintenance, high repeatability and accuracy PWM admix system.

- Admix flow rate monitoring and volume recording.

- Liquid and powder color compatible admix system.

- Digital water measurement with easy calibration.

- Full feedback measurement Electronically actuated gates with larger gate opening for increased capacity with digital feedback

- Water to cement ratio monitoring and control

The most advanced control system in the concrete industry!

Industry’s Most Accurate Control System

Concrete Genius® Control System:

- Concrete Genius® Base System (Continued)

- FastCal™ fast calibration system.

- Independent cement mass monitoring, display and recording.

- Independent rock mass monitoring, display and recording.

- Independent sand mass monitoring, display and recording.

- Automatic gate positioning with precision feedback.

- GPS capable/Theft Protection with customizable notifications

- Concrete Genius’s proprietary Concrete Cloud OPs™ capable for complete and unparalleled remote access and data management.

- Wireless remote control.

The most advanced control system in the concrete industry!

Industry’s Most Accurate Control System

Concrete Genius® Control System:

- Concrete Genius® Base System (Functions – continued)

- On the backside of the system:

- We measure each admix flow rate, the water flow rate, the aggregate flow rates, the cement flow rates, and then record this information in the cloud where only the owner of the mixer has access to this information.

- In the end, we have the most transparent system available. Not only is a batch record available but we can produce records for every reading from every second of production.

- These total over 70,000 measurements for each 10 yd. batch.

- We CAN demonstrate that not only the total batch was on spec but the entire process of batching was on spec!

- With proprietary data management and evaluation tools!

- On the backside of the system:

The most advanced control system in the concrete industry!

Connect with us today!

Please call us today at (515) 451-4020

[email protected]

www.concretegenius.com

Concrete Genius, LLC

Company Highlights

January 2023